Categories

Galvanized/PPGI/PPGL

Electro Galvanized Coil EG Coil

Electro-galvanized steel is a plating process where the steel is placed in an electrically charged solution of zinc and saline. This causes the zinc to chemically bond to the conductive steel. Electro-plating is frequently used for coiled sheet steel, which is later formed into shapes such as c-purloins, and corrugated sheets or can be formed and welded into pipes and tubes.

Electro-galvanized steel is a plating process where the steel is placed in an electrically charged solution of zinc and saline. This causes the zinc to chemically bond to the conductive steel. Electro-plating is frequently used for coiled sheet steel, which is later formed into shapes such as c-purloins, and corrugated sheets or can be formed and welded into pipes and tubes.

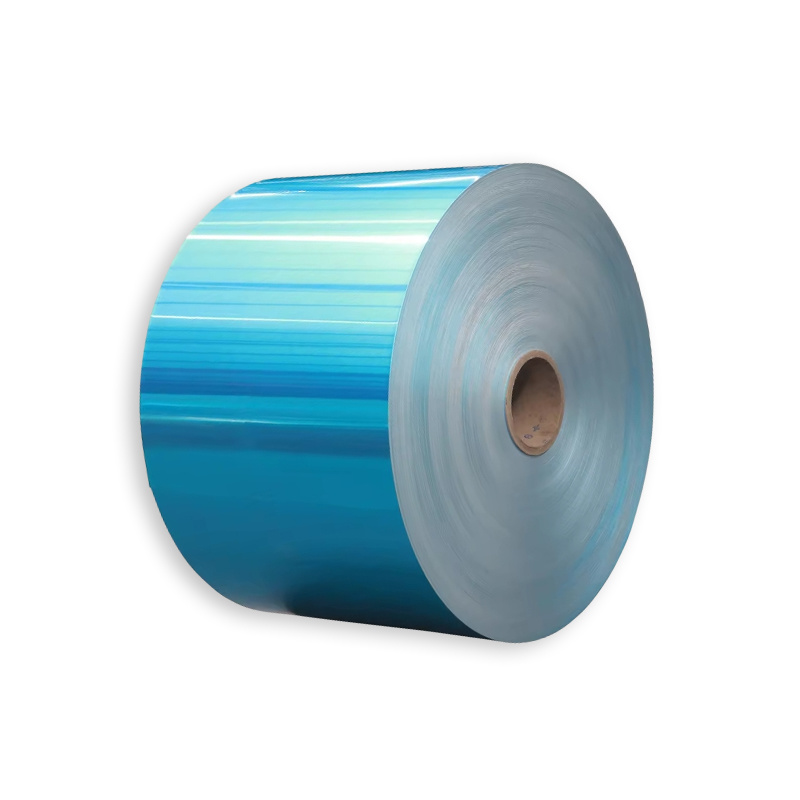

The full form of PPGI is pre-painted galvanized iron. It is a kind of color coated steel or pre-painted steel, which is an extension of GI. As the name implies, it uses zinc-coated steel as substrate, and then it is cleaned, pre-treated, and applied with layers of coatings to make it more beautiful and durable to use. We adopt the coil coating process to make PPGI coils. With slitting, shearing, and roller equipment, we also have strips, plain and corrugated sheets for sale.

PPGL stands for pre-painted galvalume steel, which is a kind of color-coated steel with GL as substrate. It combines the strength of steel with excellent anti-corrosion of Zn-Al coating. The galvalume coating is made of 55% aluminum, 43.4% zinc, and 1.6% silicon. Except for their excellent corrosion resistance, PPGL sheets also have high thermal reflectivity, which makes them heat-resisting.

Prepainted Galvalume Steel PPGL Coil

Prepainted galvalume steel coils are a type of coated steel product that combines galvalume steel's corrosion resistance with the aesthetics and versatility of pre-painted coatings. Galvalume steel is created by covering a steel substrate with a zinc-aluminum alloy, which has high corrosion resistance and durability.

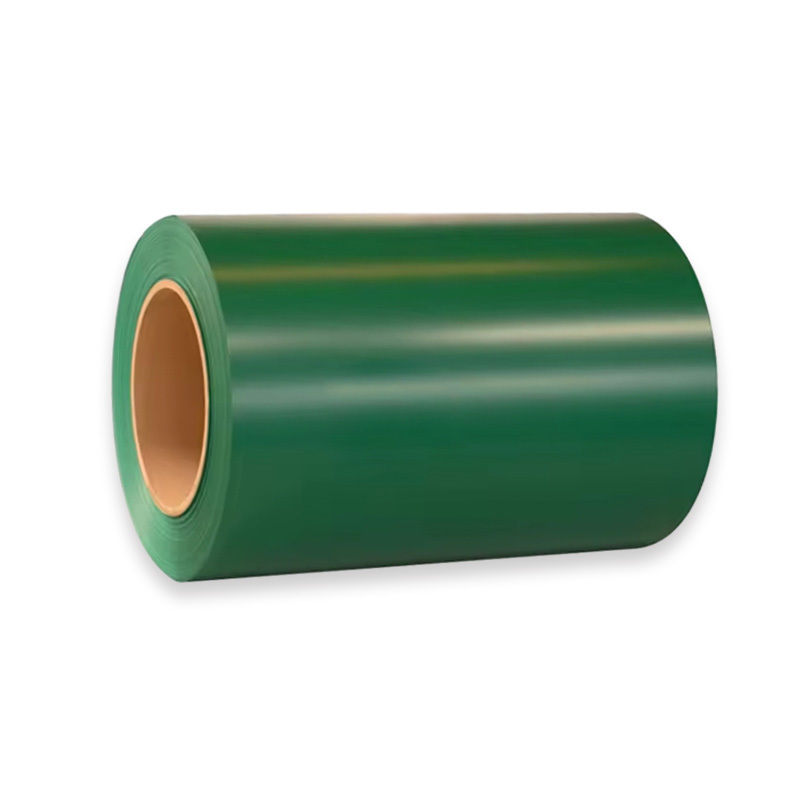

Prepainted Galvanized Steel PPGI Coil

PPGI (Pre-Painted Galvanized Iron) steel coil is a high-quality metal material widely used in construction and industrial applications. It is typically cold-rolled or hot-rolled steel that undergoes galvanization and is coated with one or multiple layers of colorful paint.

The full form of PPGI is pre-painted galvanized iron. It is a kind of color coated steel or pre-painted steel, which is an extension of GI. As the name implies, it uses zinc-coated steel as substrate, and then it is cleaned, pre-treated, and applied with layers of coatings to make it more beautiful and durable to use. We adopt the coil coating process to make PPGI coils. With slitting, shearing, and roller equipment, we also have strips, plain and corrugated sheets for sale.

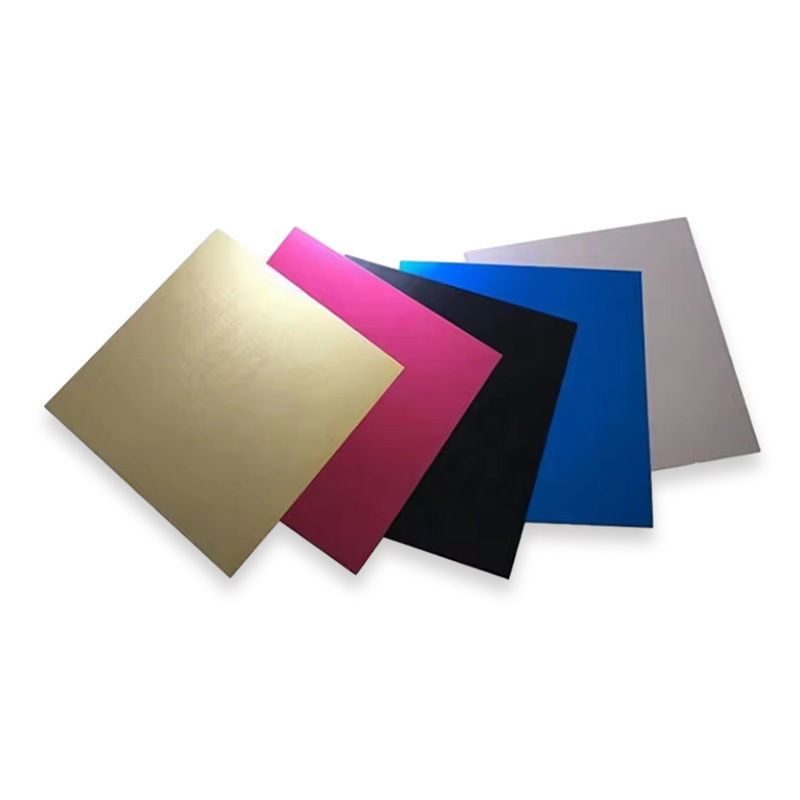

PPGL stands for pre-painted galvalume steel, which is a kind of color-coated steel with GL as substrate. It combines the strength of steel with excellent anti-corrosion of Zn-Al coating. The galvalume coating is made of 55% aluminum, 43.4% zinc, and 1.6% silicon. Except for their excellent corrosion resistance, PPGL sheets also have high thermal reflectivity, which makes them heat-resisting.

Prepainted Galvalume Steel PPGL Sheet

Prepainted galvalume steel coils are a type of coated steel product that combines galvalume steel's corrosion resistance with the aesthetics and versatility of pre-painted coatings. Galvalume steel is created by covering a steel substrate with a zinc-aluminum alloy, which has high corrosion resistance and durability.

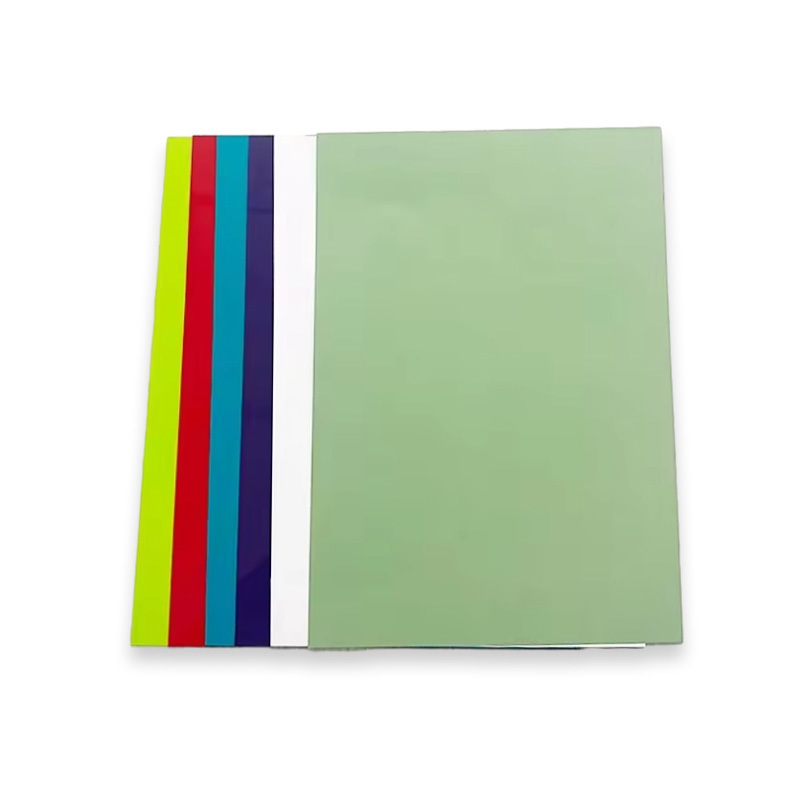

Prepainted Galvanized Steel PPGI Sheet

It is a form of galvanized iron (GI) that is also dipped into zinc. However, the zinc coat is pre-painted in the factory instead of waiting until after the steel is formed. Applying a zinc coat prevents rusting. PPGI is also known as metallic coated steels, or pre-coated steel.

A color-coated aluminum sheet coil is a type of aluminum coil that has been coated with a layer of paint or other organic coating. This layer of coating is applied to the surface of the aluminum coil in a continuous process, creating a uniform and consistent layer of color.

Color-coated aluminum coils are the surface coating and coloring treatment of aluminum plates or aluminum coils. The commonly coated aluminum coils are fluorocarbon color-coated aluminum coils and polyester color-coated aluminum coils.

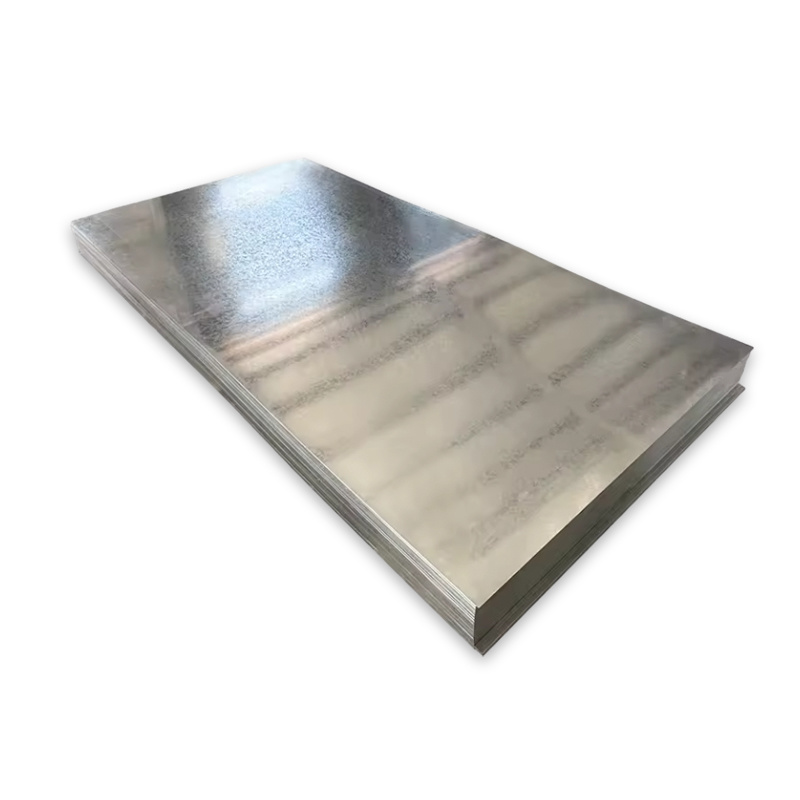

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating.

Galvanized coil is made of a type of steel that is coated with zinc for protection by an electroplating process. The galvanized layer is applied to cold rolled steel at low temperatures. So it is also known as cold galvanized steel.

Prepainted Galvanized Steel Coil

When steel components are used to make more complex finished products, they can be galvanized before the product is assembled. This is called pre-galvanizing, or "pre-galvanizing". It may also be referred to as "in-line", "continuous" or "rolled" galvanizing.

DX51D material is a mild steel galvanized layer for steel products. Specifically, DX51D is a steel grade characterized by its cold-formed bending and profiling qualities.

The Z150 in the DX51D Z150 galvanized coil is the actual coating name. The manufacturer describes the DX51D Z150 material as a mild steel galvanized layer for steel products. Specifically, DX51D is a steel grade characterized by its cold-formed bending and profiling qualities.